What kind of stepping motor is most commonly used?

Oct 31, 2022|

Oct 31, 2022| View:20

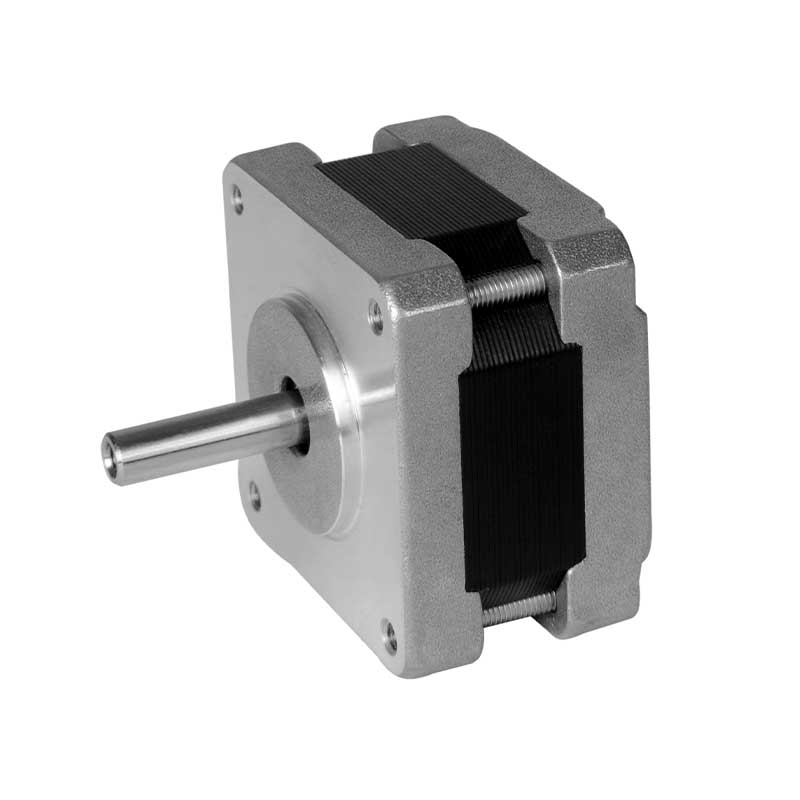

View:20The stepping motoris a kind of electromechanical device which directly converts electrical pulse into mechanical motion by controlling the order, frequency, and quantity of electrical pulse applied on the motor coil, it can control the steering, speed, and rotation angle of the stepping motor. Without the aid of the closed-loop feedback control system with position induction, the simple and low-cost open-loop control system is composed of the stepper motor and its matched drivers, and precise position and speed control can be achieved.

In industrial automation, stepping motoris widely used. The stepping motoris an open-loop control system because it can control the rotor's angular position without sensors. Similar to brushless DC motors, they rotate by holding the timing of the coil's electrification so that the magnets interact with each other.

The structure of the stepping motorcan be divided into permanent magnet type, reactive type, and hybrid type 3. At present, the most commonly used is the hybrid stepping motor, because it combines the advantages of permanent magnet type and reactive type.

Small step angle, ample torque, and good dynamic performance. The rotor of the hybrid stepping motoris special. It is composed of two steel cups with teeth mounted on the center shaft of the permanent magnet. One end of the rotor is N and the other is s, and the teeth of n and s are dislocated.

The common hybrid stepping motorhas a 1.8-degree pitch angle and a 50-tooth rotor, while the stator has only 48 teeth and is divided into eight main poles. If we divide the eight Poles into four pairs, we will find that one pair of stator and rotor teeth are perfectly aligned, and one pair of stator and rotor teeth are misaligned, the other two sets of stator and rotor teeth are half-aligned.

When given a pulse signal, the stator magnetic field changes and the rotor moves slightly to align with the stator teeth. In Full Drive, each move is a concave tooth or half of a convex tooth, this angle is 1.8 degrees. If it's a half-step drive, the angle will be further reduced, which is 0.9 degrees.

The above is about the introduction of the stepping motor, hope to give you help, if there are other questions about this, you can contact us at any time.